Effluent Treatment Plant

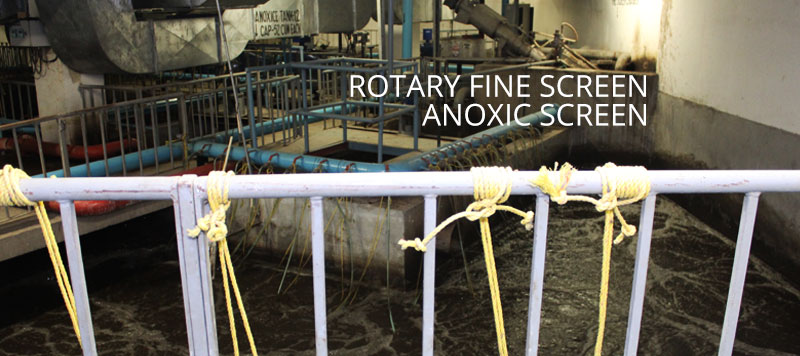

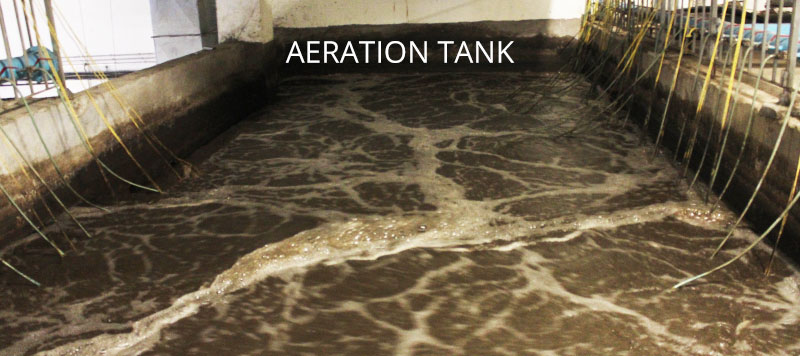

Our Effluent treatment Plants provide effective solutions to effluent odor control, BOD reduction, aeration, clarification, phosphorous and nitrogen removal and more. Our process experts work with the design team to learn the various factors that contribute to a plant’s design, including effluent requirements, land availability, energy, labor and disposal costs.

We then apply our extensive process knowledge and product expertise, analyzing the efficiency of each process, their interaction with other components, while optimizing the overall efficiency of the entire system from start to finish.

Dhal Engineering provides effluent treatment solutions for various types of industrial waste water. Customised systems to suit the wide variety of effluents and to maintain efficiency are provided to industries – systems based on physico-chemical and biological treatments and membrane separation are offered to suit efficiency. We have the experience and capability to design and commission a host of clarifiers, filters, aeration, coagulation and settling systems for waste from industries like chemicals, drugs, pharma, refineries, leachates, etc.

Recycle and reuse of treated effluents is profitable in the ever deteriorating environment of water scarcity. Reverse osmosis, ultra-filtration systems and other tertiary treatment processes make this possible for industries keen on resource optimisation

Our good practice guide deals with improving the performance of effluent treatment plant to reduce operating costs and reduce environmental pollution. Most companies operate effluent treatment plants to reduce the potential for pollution of receiving waters and to comply with discharge consent conditions. Effective management and control of the processes used for effluent treatment will help you to:

Reduce your operating costs and thus increase profits.

Achieve more effective compliance with legislation.

Improve your company's public image.

Effluent Treatment System

Currently, industrial effluent treatment system technology employs not only stand-alone equipment and facilities, but also total systems that function under a comprehensive concept.

Such concepts include pH neutralization processing, coagulating sedimentation treatment, pressure floatation treatment, bio oxidation processing, and filtering and absorption processing.

We provide complete industrial effluent treatment systems with the mission of saving the environment from destruction and returning the earth back to its natural condition.

Effluent Recycling Plant

Dhal Engineering offers an effectual range of Effluent Treatment Plants for recycling of wastewater to reduce water demand. The comprehensive treatment solution works at various levels and involves various physical, chemical, biological and membrane processes. We also provides effluent treatment solutions for various types of industrial waste water. Customized systems to suit the wide variety of effluents and to maintain efficiency are provided to industries. These systems include physic-chemical treatment, biological treatment, tertiary treatment and membrane separation process to achieve the zero-discharge standards laid by statutory authority. We provide innovative and economical systems for waste from industries like chemicals, drugs, pharmaceutical, refineries, dairy, ready mix plants & textile etc.

Industrial Waste Water Treatment Plant

Once water has served its numerous industrial uses, it must be treated to be reused, treated to enter the public utility wastewater treatment process or treated to return to the environment in a manner consistent with water quality regulations.

From the main effluent sump to discharge, we provides durable and reliable products and systems to move, manage and treat industrial wastewater along the entire length of the treatment process.

Industrial wastewater treatment covers the mechanisms and processes used to treat wastewater that is produced as a by-product of industrial or commercial activities. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sanitary sewer or to a surface water in the environment. Most industries produce some wastewater although recent trends in the developed world have been to minimise such production or recycle such wastewater within the production process. However, many industries remain dependent on processes that produce wastewaters.

Ultra Filtration

Ultra Filtration is a membrane fractionation process used to separate and concentrate macro-molecules and colloids from water. Ultra Filtration is most reliable and economical solution for the removal of impurities such as bacteria, heavy metals and suspended solids. Substances smaller than the particle size of the membrane are passed while large solutes or particles are rejected.

The typical molecular weight cut off (M.W.C.O.) of Ultra Filtration membranes ranges from 1,000 to 1,00,000 daltons. Because of its larger pore size, it does not reject dissolved salts but removes colloidal solids such as silica, iron and some T. O. C. contaminants.

R O System

Reverse Osmosis is reversal of natural process of osmosis - a process by which a dilute solution will pass through a semi-permeable barrier to a more concentrated solution. In reverse osmosis, a pressure in excess of osmotic pressure is applied to a concentrated solution, forcing essentially pure water through the semi permeable membrane, leaving behind the dissolved solids. The result is a pure, essentially mineral-free stream of water.